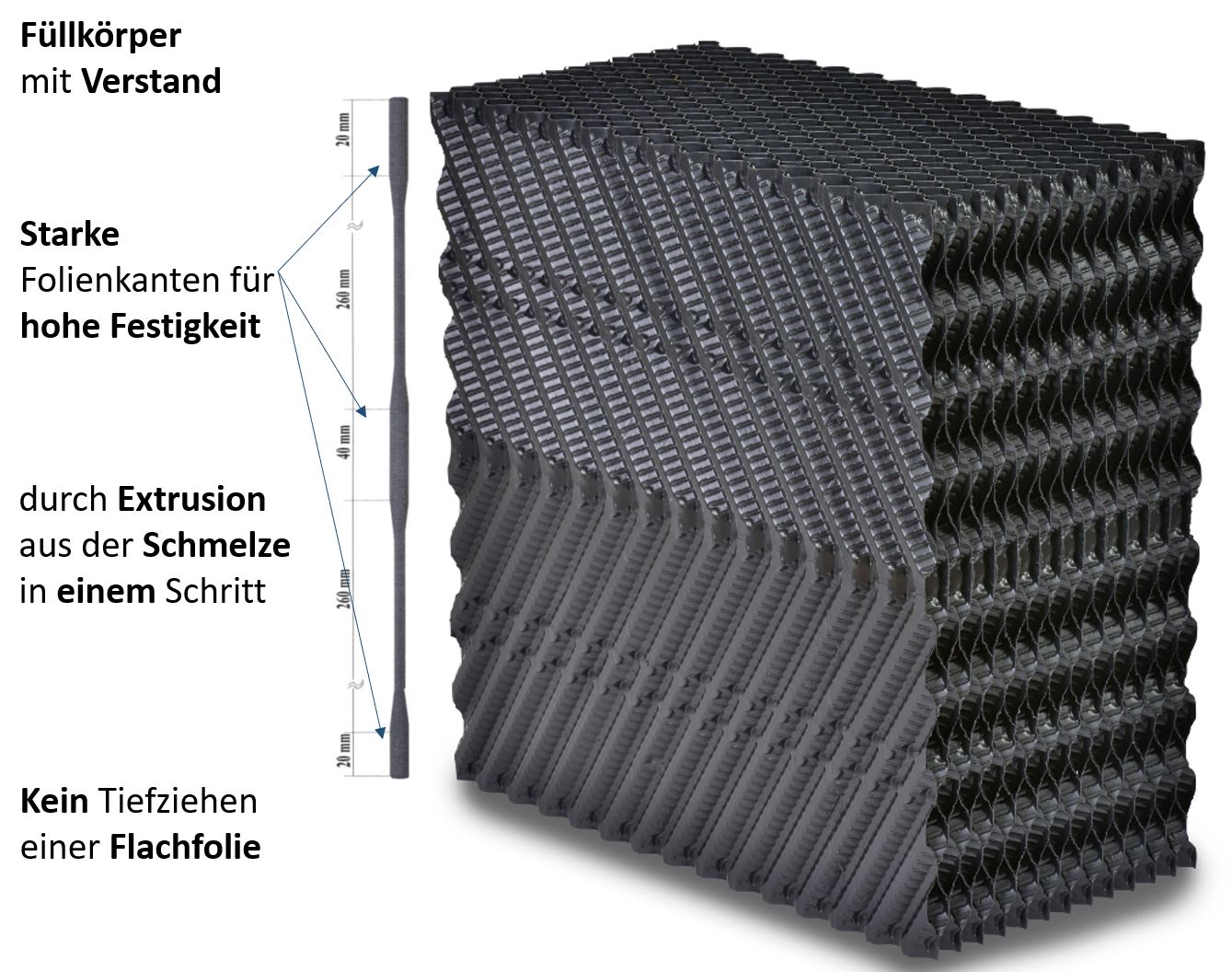

Hewitech, a family run company was founded by Frank Dirkskötter and Nicole Hewing in 1993. Starting up as a "one-man business" in the field of special machine construction, the company grew continuously with the objective of producing reliable and efficient machines for the plastics processing industry. These included forming systems, tools, rotary systems, welding and cutting equipment, material loading stations and dispensing / mixing equipment. The well-known PP film installations bear the hallmark of Hewitech - melt extrusion and welding into blocks - decades of experience. We manufacture directly from granules and not from purchased expensive flat films! In addition, modern production technology allows us to achieve 'product-optimization' directly from the melt, which has convinced our customers for decades!

INJECTION MOULDING TECHNOLOGY - SUSTAINABLE GROWTH

In the course of development, investments were made in plastic injection moulding technology with large moulding equipment together with the development of special processes for the applications of cooling tower installations and rainwater retention. These set new standards for the market operators in the components business!

Powerful cool-down systems have been made with innovative highly efficient fill designs in almost any shape and structure using polypropylene material which led to an unforeseen change on the cooling tower market at that time. Significant performance improvements in cooling capabilities, increased efficiency levels in power plants as well as using a healthier material than PVC, created the breakthrough for sustainable growth for the young company.

This was accompanied by the construction of a specially developed experimental cooling tower, whose design and measuring method was at the time decisive for the development of high-performance cooling installation packages. In this twin cooling test stand, product designs could be quickly compared and developed under the same conditions. These results are still relevant today for calculating cooling performance and pressure reduction within the cooling tower applications.

- Company policy (42 KB)

INJECTION MOULDING

The injection moulded parts developed by us are used in various fields, such as Rainwater infiltration, adiabatic cooling systems and the production of fills for cooling towers. In these areas, we rely on constant and further innovative development. Specially developed manufacturing methods and the continuous testing of new materials (including lotus effect) in our in-house test facilities guarantee precision and high performance.

SPECIAL MACHINE CONSTRUCTION

In the Hewitech CAD design department ideas and tasks are formed. The in-house (CNC) tool and special machine construction create independence and allow for the shortest possible development and production time for new machinery and plastic components.

Experience and sound knowledge are the best prerequisites for optimum design and production.

THE THIRD REVOLUTION: INLINE- Film extrusion from the melt.

The processing of plastic granulates, as well as the installation of dispensing and conveying units could be used through our expertise of machine construction. In 2005 the processing of plastic granulates, combined with the installation of dispensing and conveying units, enabled Hewitech to initiate further development steps to produce structure films directly from the melt. Here, the INLINER film extrusion process was created with a 100% higher plastic mass output, as well as a significantly better design and structured precision of the films. This was a further milestone in supplying an ever-increasing amount of large-scale projects, not only in cooling tower applications but also in large trickling filter water treatment plants worldwide.

INNOVATIONS distinguish us in efficient production techniques, novel and performance-enhancing product design (including customer-specific configurations) as well as specialised solutions together with our machine and tool construction. Over the years this has been honoured by our customers in a variety of applications and operational areas.